Why AI Chip Manufacturing Is Challenging: Global Semiconductor Leaders, and Canada’s Role in the Industry

Introduction

The race to develop powerful AI chips is one of the most complex engineering challenges today. AI chips are the backbone of artificial intelligence applications, from deep learning models to autonomous vehicles. However, manufacturing these chips is extraordinarily difficult due to the need for atomic-level precision, high production costs, and a complex global supply chain.

This article explores the challenges of AI chip manufacturing, the dominant players in the industry, and why the Netherlands has succeeded in semiconductor manufacturing while Canada has lagged behind.

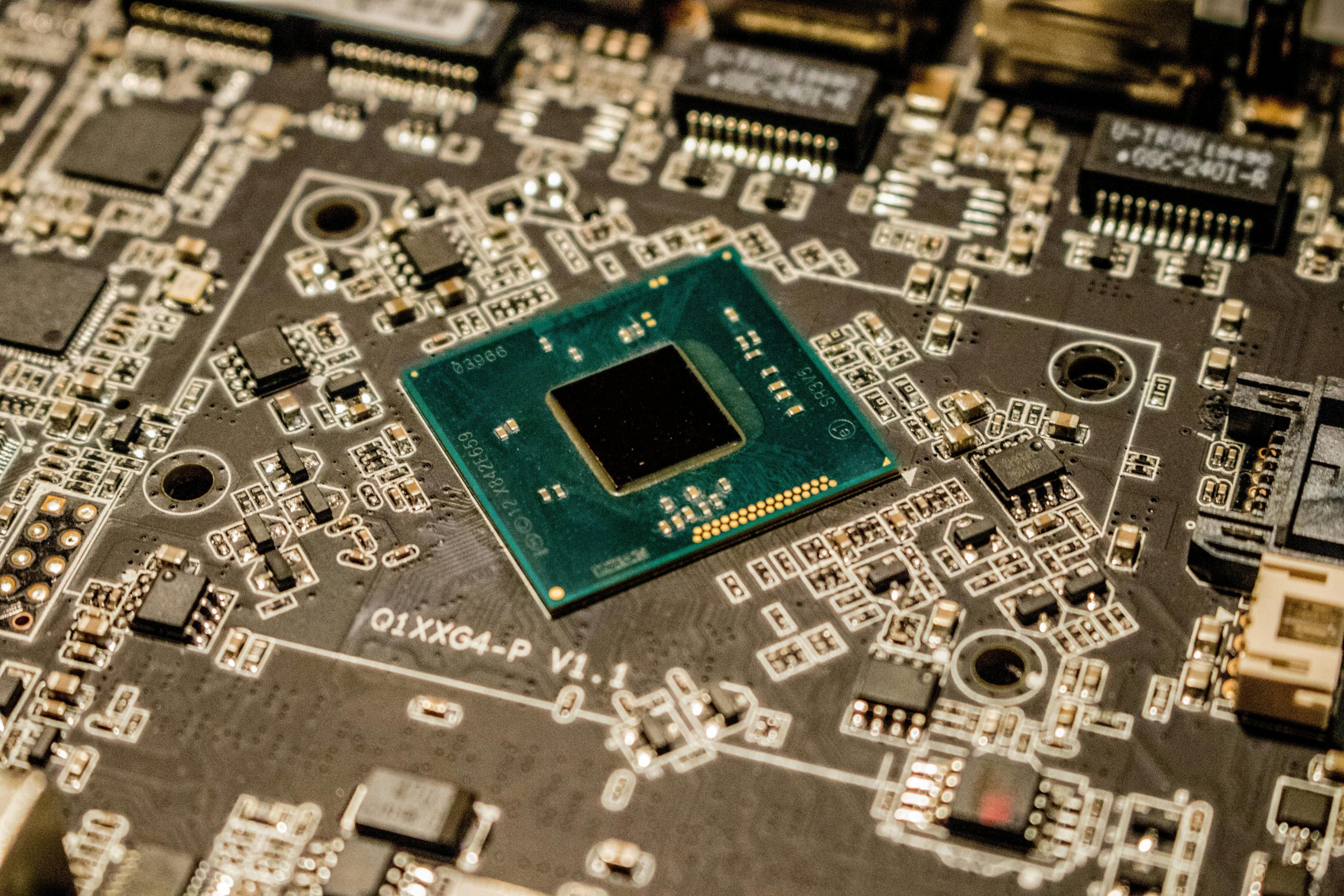

Understanding AI Chips

AI chips are specialized processors designed to accelerate machine learning and deep learning tasks. Unlike general-purpose CPUs, AI chips are optimized for parallel computations, making them essential for applications like data centers, robotics, and AI-powered analytics.

Key Characteristics of AI Chips:

- Parallel Processing: Handles multiple computations simultaneously.

- High Throughput: Can process large amounts of data efficiently.

- Energy Efficiency: Optimized for power consumption to minimize heat generation and operational costs.

- Specialized Architecture: Includes tensor cores and matrix multiplication units for deep learning.

Why Is AI Chip Manufacturing So Hard?

1. Extreme Precision at the Atomic Level

Modern AI chips are produced at nanometer scales, with transistors as small as 3nm (nanometers). To put this into perspective:

- A human hair is approximately 80,000nm thick.

- A single transistor in a 3nm chip is about 10 silicon atoms wide.

These chips require EUV (Extreme Ultraviolet) lithography, an ultra-precise process that allows for the printing of incredibly small circuits. The challenge? Only one company in the world, ASML (Netherlands), can make these EUV machines.

2. The Insane Cost of Fabrication

Building a semiconductor fabrication plant (fab) is among the most expensive industrial projects:

- A new 3nm or 5nm fab costs $15B-$20B (TSMC, Intel, Samsung).

- Even older fabs (12nm, 28nm) cost $5B+.

- Each EUV machine costs ~$350 million, and a single fab requires dozens of them.

Breakdown of Costs:

| Process | Estimated Cost |

|---|---|

| EUV Machines (ASML) | $350M each |

| Clean Rooms (dust-free environments) | $500M+ |

| Water & Electricity (fabs use more than entire cities) | $1B+ |

| R&D for Chip Design | $10B+ |

The sheer capital investment required to enter this space is a major barrier.

3. The Complexity of AI Chip Design

A single NVIDIA H100 AI GPU contains:

- 80 billion transistors

- 5nm process technology

- HBM3 (High Bandwidth Memory) with speeds over 3TB/s

The challenges of designing AI chips include:

- Optimizing performance while reducing power consumption.

- Managing heat dissipation, as AI chips consume 500+ watts.

- Ensuring reliability, since even tiny defects can ruin an entire chip batch.

4. No One Company Can Do Everything Alone

Unlike software, where a small team can innovate rapidly, semiconductor manufacturing requires collaboration between multiple fields:

- Material Scientists – Develop ultra-pure silicon wafers.

- Electrical Engineers – Design logic circuits and memory systems.

- Manufacturing Experts – Oversee lithography, etching, and doping.

- Software Engineers – Build drivers, compilers, and AI frameworks.

Even NVIDIA does not manufacture its own chips; it relies on TSMC and Samsung Foundry.

5. AI Chips Need Specialized Memory & Interconnects

AI workloads require incredibly fast memory to function efficiently:

- HBM3 (High Bandwidth Memory) used in NVIDIA H100 offers 3TB/s bandwidth.

- Traditional DDR5 RAM, in contrast, offers only 50GB/s – a 60x difference.

- HBM uses stacked layers of DRAM, requiring precision bonding at the nanometer scale.

If memory interconnects fail, the entire AI chip becomes useless.

6. Supply Chain & Geopolitical Challenges

Chip manufacturing relies on a global supply chain:

- USA: Chip design (NVIDIA, AMD, Intel, Apple)

- Taiwan: Manufacturing (TSMC produces 90% of the world’s advanced chips)

- South Korea: Memory chips (Samsung, SK Hynix)

- Netherlands: EUV lithography machines (ASML)

- China: Some fabrication, but lags in technology (SMIC)

Geopolitical Issues:

- U.S. sanctions prevent China from accessing 5nm and 3nm technology.

- Taiwan’s strategic importance means any disruption there could cripple the global semiconductor supply chain.

The Netherlands vs. Canada in Semiconductor Manufacturing

Why the Netherlands Succeeded (ASML) and Canada Didn’t

1. The Netherlands Created ASML (EUV Monopoly)

ASML is the only company in the world that makes EUV lithography machines, which are required for modern chips. Without ASML, TSMC, Samsung, and Intel wouldn’t be able to produce 5nm, 3nm chips.

2. Canada Focused on AI, Not Manufacturing

While the Netherlands developed ASML, Canada prioritized AI research. Institutions like the Vector Institute and researchers like Geoffrey Hinton made Canada a leader in AI software, but not semiconductor manufacturing.

3. Lack of Government Investment

- The Dutch government invested billions into ASML.

- Canada has no equivalent semiconductor strategy.

Can Canada Enter the Semiconductor Industry?

Yes, but it requires massive investment and strategic partnerships.

Steps for Canada to Compete in AI Chip Manufacturing:

- Design AI Accelerators (Edge AI, Cloud AI, or Medical AI).

- Prototype using FPGAs & small-batch ASIC production.

- Partner with TSMC, Intel Foundry, or GlobalFoundries for mass production.

- Create a Canadian CHIPS Act to fund semiconductor R&D.

- Work with universities (U of T, McGill, UBC) to train semiconductor engineers.

🚀 Goal: Build AI accelerators in Canada while using TSMC for fabrication.

Sources

- ASML EUV Lithography: https://www.asml.com

- TSMC Manufacturing Process: https://www.tsmc.com

- NVIDIA H100 AI GPU: https://www.nvidia.com/en-us/data-center/h100/

- Global Semiconductor Supply Chain Analysis: https://www.semiconductors.org